Most wetsuits have seams and there are differences between them in how they are sealed or how the quality is lasting.

In general good wetsuits are made of neoprene panels and they are first glued together and then blind stitched. This way the seam is strong and properly sealed.

What are the advantages and disadvantages of a seam?

There are some disadvantages:

- Leaking water

Besides the zipper, the seams are the most likely to leak water and heat. So fewer seams should be warmer in the end. - Reducing flexibility

Also besides the zipper, the seams have less stretch than the neoprene. Especially around the underarms and shoulders, there should be no or fewer seams. From my personal experience, I would say that a seam at your ass can be a bit tricky. Because you are bending a lot during surfing or kiting and if the seam is not holding it anymore after a while it could break and you have a hole in your ass. - Chafing or sanding

I never had this experience but some people do. It could be that they have sensitive skin or because they purchased a cheap wetsuit. A good solution for it is wearing a lycra or bodysuit underneath your wetsuit.

The advantages of having seams:

- Better fitting

To make the wetsuit in the right shape, and design and to have a comfortable wetsuit they need to adjust the neoprene panels, therefore they need the seams. But the development of wetsuits shows nowadays that they need fewer seams because the quality of the neoprene is getting better. So maybe in the future, we will have only seamless wetsuits on the market.

How is a wetsuit stitched?

The most common and used ways of stitching are described below. There are a couple more ways of stitching but not used a lot like e-stitch, double-needle, and zigzag stitching.

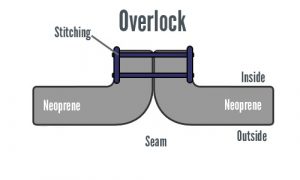

Overlock

This is one of the most basic ways of stitching. They also use it with normal T-shirts in the fashion industry. This way of stitching is mostly used in cheaper wetsuits or thin wetsuits under 2mm neoprene (summer wetsuits). Overlock stitching is less flexible and less water-sealed. Another problem is that the stitch is creating a bugle inside the wetsuit and could be irritating to your skin. However, it’s rare to find a wetsuit with overlock seams these days. These seams are mostly used in Lycras or rash vests.

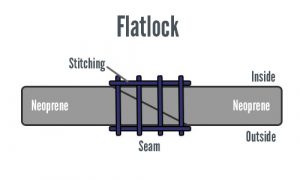

Flatlock

Flatlock stitching is a flexible and strong way of making seams. The only disadvantage is that while making this seam they need to make many holes through the wetsuit resulting in more water leaking and less warmth. They usually use this technique with summer wetsuits or suits less than 2.5 mm neoprene thickness.

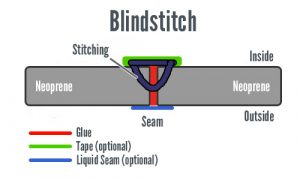

Blindstitch

Wetsuits of higher quality and mostly higher prices use this technique. These seams are first glued together (sometimes three times glued) and then they stitch halfway through the neoprene so there is no hole or opening for the water to get through. So you get a strong, flexible, and sealed seam that can perfectly be used in a winter wetsuit to keep it warm. You also have this version with a Doubleblindstitch that is mostly used for thicker wetsuits so they can be blind stitched on both sides. The result is a much stronger seam of course.

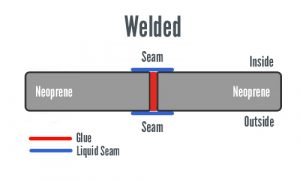

Welded

A welded seam uses a silicon-based glue or kit between two neoprene panels to seal the wetsuit. There is no stitching in the wetsuit so no holes through the neoprene. That means 100% waterproof and will keep you warm. Only high-end wetsuits use this technique and say it is strong, really stretchy, and durable.

How is a wetsuit sealed?

Every wetsuit seam is sealed with a certain glue but to make it more durable and strong some of the more expensive wetsuits have something extra to seal it.

Glued seams

The neoprene panels are glued together making it a strong and sealed (waterproof) seam.

Spot taped seams

Some of the seams have elastic tape (neoprene tape) glued at the inside of the seam. Mostly in critical areas to add additional strength where needed, for example, the angle of the neoprene panels.

Fully taped seams

Tape is glued inside every seam to strengthen and seal the seam even more. Neoprene tape is used to not lose its flexibility. The tape protects the skin from irritation with the seams as well.

Liquid taped

Liquid sealed or fluid sealed, is a liquid rubber layer over all seams. This layer protects the seam even more from water entering the wetsuit, so it will be 100% sealed. It is also making the seam more durable because the stitches are protected by the rubber.

Summary

- Most wetsuits have seams and there are differences between them in how they are sealed or how the quality is lasting.

- There are some disadvantages: Leaking water Beside the zipper the seams are the most likely to leak water and heat.

- Chafing or sanding I never had this experience but some people do.

- The most common and used ways of stitching are described below.

– wetsuit blindstitch seam - Every wetsuit seam is sealed with a certain glue but to make it more durable and strong some of the more expensive wetsuits have something extra to seal it.